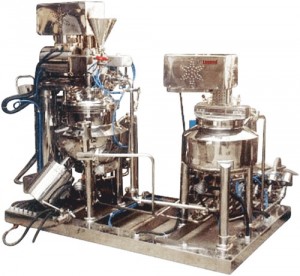

R & D model Automatic ointment\cream manufacturing plant

Legend Automatic ointment\cream manufacturing plant (R & D Model) is a versatile Ointment manufacturing unit for mixing, emulsifying and producing very fine emulsions/suspensions in a single compatible machine. The plant is equipped with Semi Contra design agitator with blades having holes to cut the mass while Jackets have provision for both heating & cooling with temperature controller.

Hydraulic Power Pack with cylinder is provided to lift complete agitator assembly with top lid for product recovery / Easy to cleaning / Changeover of batch & for maintenance. Watering vacuum pumps are provided to create vacuum in Mfg. vessel and transfer other ingredients i.e. molten wax / Hot water in Mfg. Vessel. “W” shaped Low speed Anchor Stirrer with self-adjustable Teflon scrapper & 2 stationery baffles is provided for better stirring, for transfer of the complete product and to avoid wastage.

Automatic PLC based control system ensures easy control of various parameters such as Heating, Cooling, Stirrer timing, Homogeniser Timing, Stirrer speed, Homogeniser speed, Vacuum, Pressure, CIP etc.

Large variety of products can be manufactured due to the highly flexible dispersing and homogenizing system and thus our manufacturing plant finds its application in pharmaceutical and cosmetic industries. Our exclusive ranges of cGMP based Ointment manufacturing plants (R&D) are available in capacities from 5 kg. to 50 kg.

Salient features :

Technical details, specification & designs are subject to change without any prior notice.