Fluid bed Dryer

Fluid Bed Dryers (FBD) are primarily used in almost all chemical, pharmaceutical, food, dyestuff and other process industries to dry materials by fluidization with hot and / or dehumidified air, which creates a turbulence in the wet product (not totally liquid) while flowing through it.

Working Principle:

The atmospheric air is sucked in the dryer through 5/10 micron filter by efficient dynamically balanced fan driven by an electric motor.

The clean air then passes over the electric heaters / steam or radiator provided with controller. The hot air passes through the product and fluidization dries the product. Dryer is provided with dehumidifier (Chilled water system) at the inlet so as to dry the product at low temperature under fluidized condition.

The blower speed is controlled by AC frequency drive so as to control the fluidization avoiding choking of the filter bag. A raking system is provided to avoid lump formation in the container to achieve uniform fluidization and uniform drying.

A model with complete automation and PLC, automatic bag shaking and with MIMIC is also offered.The drying time depends on various factors such as physical properties of material, moisture content, type of moisture (free or inherent or water of crystallization), drying temperature etc. For example, the crystalline product can be dried faster than amorphous product containing same percentage of moisture at same temperature.

Salient features :

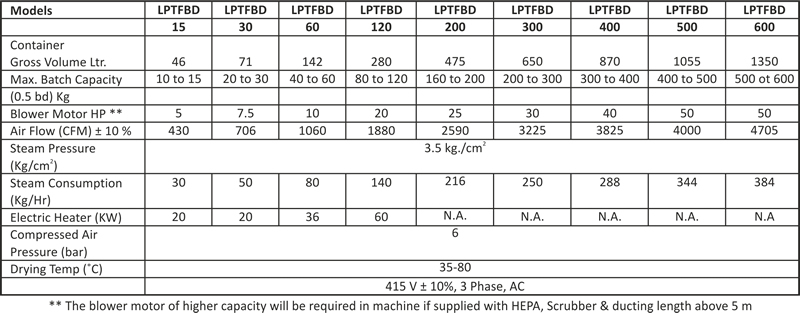

Technical details, specification & designs are subject to change without any prior notice.